What’s New?

What’s New?

- Cause of well casing pipe damage and repairing technology

- How many steps are needed in the process of pipelines built?

- What are the commonly used welding methods for oil pipelines

- Do you know new anti-corrosion technologies for pipelines

- Development trend of global continuous pipe drilling technology

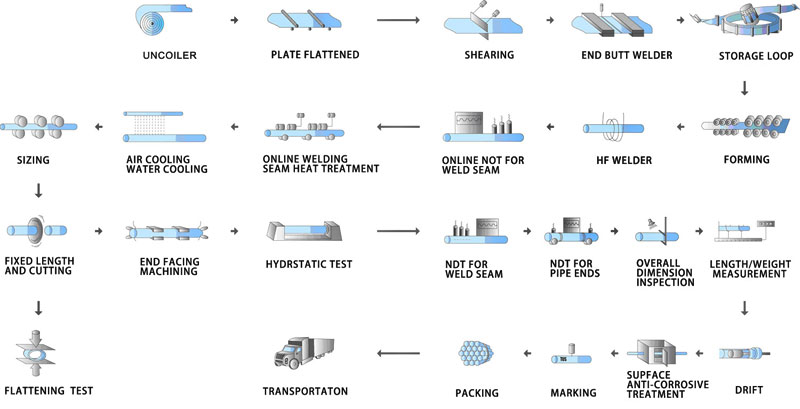

Technological process for OCTG line pipes

What is pipeline process technology?

The manufacturing process of the line pipe is similar to the tubing and casing. What's more, there are several procedures that are of great importance. Because the line pipe is divided into welded pipe and seamless pipe, so there is a slight difference in manufacturing process between welded pipe and seamless pipe. For example, Seamless steel tube is once-shaping in the rolling, while welding steel pipe need to weld after roll, which is generally divided spiral welding and straight welding.

Productive process of linepipe

A . Seamless Pipes

- Ingot heating

- Perforation

- Rolling and sizing

- Cooling

- Straightener

- NDT, UT

- End cutting

- Coupling thread (permium thread available)

- Hydrostatic test, x-ray test.

- Painting and thread protecting

- Packing

B. Welding Pipes

- Open

- Cutting

- Welding

- Shaping

- Polishing

- CorrectingHeat treatment

- Eddy Current Test, Cutting

- HT

- Pickling and inspection

- Painting, packing